SORAKO Jigsaw Tool Review

I was asked to review another SORAKO tool. And after the pleasant experience with the SORAKO chainsaw, I was happy to give their jigsaw a try.

The SORAKO 800-3000SPM Jigsaw with orbital function. |

The SORAKO 800-3000SPM Jigsaw With Blades & Scale Ruler came to the shop. And I was eager to use open it and read the instructions so I could plug it in and try it out. It comes with wood and metal T-shank blades, a straight cut fence (aka... scale ruler), and Allen wrench (Hex key). It also comes with a safety shield that attaches just in front of the blade mechanism and prevents debris from flying up and causing injury. Along with that, it comes with some other cool features. |

|

The SORAKO jigsaw has an easy to adjust Obital setting.

The SORAKO jigsaw toolless blade change system. |

|||||||||

Cutting out a hole with the SORAKO jigsaw.

There is a noticable difference between the scrolling jigsaw blade and a standard wood cutting jigsaw blade. |

I wanted to use the jigsaw on some scrap first to get a feel for some of the features on it. Mainly the oscillating feature. I have apparently been living under a rock, because this was new to me. But they have been around for awhile. This feature can be handy, but also can cause some problems if used for the wrong cutting task. What it does is pull the blade back, away from the cut on the non-cutting stroke. This allows the chips to clear and makes a for a faster cut. The down side of this is that it creates more tear out along the cut. There are 3 settings for the orbital cut besides the 0 setting, which is straight up and down. 1 being the mildest oscillation and 3 being the most aggressive. I tried all 3 while cutting a hole. All 3 worked, however, I got a cleaner cut from setting it to 0. I can see the appeal of using the more aggressive oscillating setting in construction or when speed is needed and you don’t mind a little tear out. But if you want the clean, sharp cuts, it’s best to avoid it. And in situations where you’ll be cutting out a circle as I did, or around curves, it tended to cause me to over cut with more tear out than I cared for. The jigsaw itself performed wonderfully. Once I set the oscillation to 0, it cut the circle in a good amount of time and gave me a very accurate and quality hole. |

|||||||||

| I then went on to try the scrolling blade they had sent with the SORAKO jigsaw for me to try. This jigsaw blade for scrolling is noticeably shorter and thinner than the other blades. I’m not so great at making scrollsaw patterns so I went to my friend’s website, SimplyWoodenCreations.com, and grabbed one of his. He also has a YouTube channel by the same name and does a live show almost every Saturday at 8pm Eastern time. I chose a scrollsaw pattern that says something I say all the time. You see, I screw up and do stoopid things in my shop quite often. And you just can’t fix stoopid. So I printed out the pattern and used some adhesive spay to attach it to a piece of Luan plywood. Then drilled some holes to put my blade into and began cutting. |

|

|||||||||

Using the SORAKO jigsaw as a scrollsaw.

The finished scrolling project I did with the SORAKO jigsaw. |

I made sure the SORAKO jigsaw was speed was set to a slower speed. Normally for cutting wood I’d set it somewhere between 4 and 6. But I found that slowing the speed down to 3 worked best for doing the scroll work on the 1/4“ Luan. I tried to make use of the holes I’d drilled for making sharp turns, but in some places I had to put the old skill of cutting, backing up, cutting, and sort of whittling away enough material until I could make that turn. It’s just something you have to practice to get good at. The SORAKO 800-3000SPM jigsaw did a fine job of it. And cut surprisingly clean. Making precise cuts for scroll work is a lot to ask from a jigsaw, but I was very pleased with it. Please note, I am a long way from being a scrollsaw artist. |

|||||||||

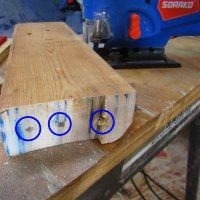

| The next thing I tried it on was cutting through metal. From time to time I do work with pallet wood and need to cut through nails and sometimes screws. I drove some sinker nails in the end of a 2x4. I also drove a yellow zinc screw into it, just to see what it would do. It cut through the 10 penny nails like they were butter. Then I got to that yellow zinc screw, which is harder. It did not want to be cut. I pushed on it and worked it, but the saw simply would not cut it. It finally worked through enough that I could whack it off with a hammer. But it never really got through it. I believe it has something to do with the strength of the yellow zinc screw and how it’s made. I checked the blade I was using after it had cooled down enough to touch it and it was still sharp. I don’t work with metal much, so there is a great likelihood that it was just me not knowing what I was doing. I was impressed that the tool held up so well. I was scared I was pushing it too hard and would have burned the motor up. |

The result of cutting nails with the SORAKO jigsaw |

|||||||||

Click here to learn more about the 5.0A, 800-3000SPM Jigsaw With Blades & Scale Ruler |

Other than that one screw, the SORAKO 800-3000SPM jigsaw held up well and worked great. It made the precise cuts needed to do the scroll work I did and was heavy duty enough to cut through the 2x4 with nails in it. Please click here to learn more and to purchase the SORAKO 800-3000SPM Jigsaw for yourself. And the video of me doing all that I mentioned is below. Have a lovely day! |

| |

Redneck Know How Blog